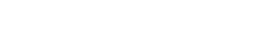

AUVs customization VS standardization

More sensors don’t automatically mean better missions.

Observations from the underwater domain.

Adding sensors often feels like progress. More data. More insight. More capability.

But when payload sensors are combined with navigation and positioning systems, the number of possible configurations grows exponentially.

Very quickly, each AUV becomes a quasi-unique configuration.

This leads to tailor-made systems:

– optimized for a specific mission

– precisely tuned to operational constraints

Clear advantage: high mission relevance.

But also clear drawbacks:

– low levels of industrialization and standardization

– higher integration and qualification risks

– increased operational and maintenance complexity

– longer mission preparation, validation, and training

In many cases, customization increase the cost, improves performance but it can also reduce robustness and repeatability

My perspective: the real AUV revolution, and their true democratization, will be accelerated through standardization. Rather than offering a generic carrier and selecting payloads for each project, it may be more effective to deliver standard AUVs designed to directly address clearly identified mission needs.

Not to cover every edge case, but to:

– address 80% of operational demands with proven, repeatable systems

– accept that the remaining 20% will still require traditional custom developments

Underwater, restraint in configuration and clarity in mission design are often strengths, not limitations. Customization should remain a powerful tool but standardization should become the default if we want to meet rapidly increasing demand.

How do you balance mission specificity with reliability, simplicity, and industrial scalability in your AUV projects?

👉 Link : https://www.linkedin.com/posts/vidal-teixeira-672a27b2_auv-autonomousunderwatervehicles-underwaterrobotics-activity-7408785442449543168-FU4J?utm_source=share&utm_medium=member_desktop&rcm=ACoAADgbq5IBdJEba6NSrWg-B7x4okZyTK9q-DQ